FFKM is the ASTM D1418 designation for perfluorinated elastomers which are copolymers of TFE (tetrafluoroethylene) and PFVE (perfluoroalkyl vinyl ether) with a cure site monomer for crosslinking. Due to its fully fluorinated backbone, FFKM has the highest level of chemical and thermal resistance of all rubber materials, therefore it is primarily used in the most critical applications.

{{ items.title }}

There are multiple cure systems that crosslink FFKM polymers. Each has its own advantage and limitation that should be assessed prior to use. Selecting the right cure/polymer combination is then important to ensure optimal sealing performance and service life.

The chart below shows a comparison of the common cure systems and their general characteristics. It’s worth knowing that formulations and/or proprietary catalysts cause big difference (sometimes huge) therefore users are advised to refer to individual spec sheets for more information.

{{ items.title }}

The information contained herein are, to the

best of our knowledge, reliable.

However, it shall not serve as guarantee or warranty, material selection and product

{{ items.title }}

Hardness

Shore A ±5

{{ items.shore }}

{{ items.color }}

Temp Range Continuous

{{ items.temp }}

In the early days, FFKM was almost exclusively used in Aerospace and Oil & Gas applications where seals were exposed to high temperature, fuels, corrosive lubricants, etc. But it is now widely used because

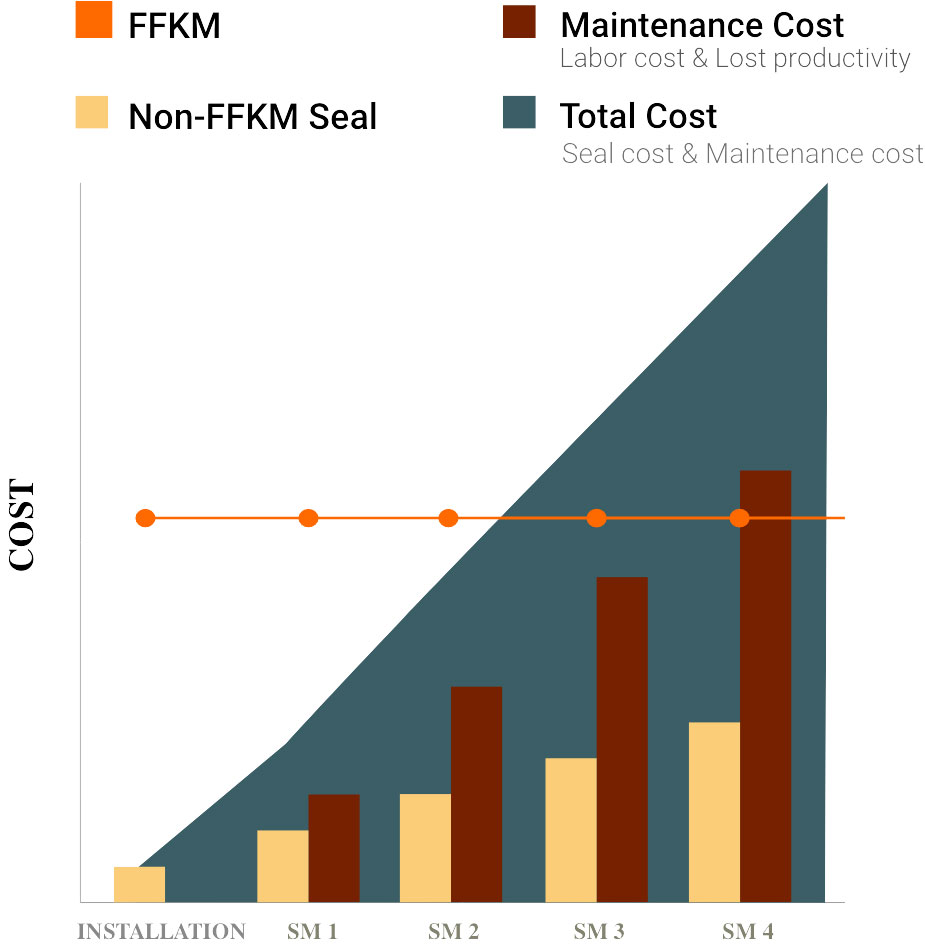

When faced with applications that are harsh but not too extreme, user can either call for FFKM or lower performing materials, such as FKM. The latter is often preferred by their buyer, but the purchase is actually made at the expense of much shorter service life and subsequent repairs. Scheduled maintenance needed to replace degrading seal incurs labor and lost production during downtime. These cumulative costs would eventually justify the use of FFKM, despite the higher piece price.

FFKM’s advantage to improve MTBM (Mean Time Between Maintenance) and COO (Cost of Ownership) should be taken into account when evaluating seal application and purchase.

Customer Satisfaction Survey

Jan-Jun 2020